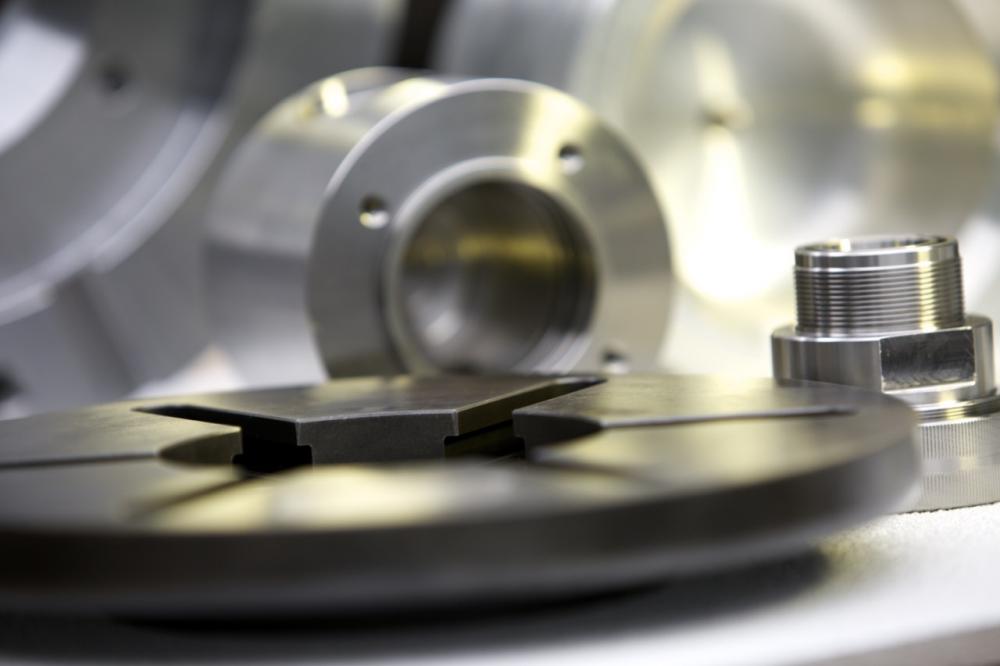

In rest machining department, we have all machines that allow us to create special one turning and turning centres. Those have counter spindle, C / Y-axis and front and axial driven tools to realize the most complex parts, so that each location works in a single cycle both faces of the commissioned product.

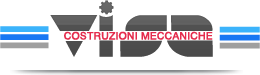

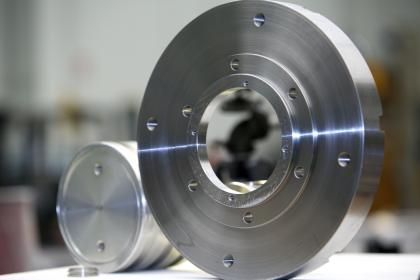

The different type of machine allows to manufacture a product machined, milled, drilled, tapped (with a diameter up to 520 mm and a maximum length of 1200 mm), supported by hydraulic bezel.

The materials are soft steel, iron, alloy and high-alloy steel, hardened, stainless steel, duplex, aluminium, brass, bronze and plastics. Both from fusion or from bar.

We meticulously control each order in the measuring room with the help of a new CMM 3D coordinate high performance, offering a CMM accurate that is able to capture the most particular of small pieces, thanks to its advanced optical components.